By Patrick Valentine, PhD

Uyemura International Corporation

Southington CT

Abstract

Poor quality is costly, and remediation costs can be significant. For an organization to improve, it must have a culture that embraces change. Continuous improvement and problem troubleshooting are integral to using Lean Six Sigma in global manufacturing industries. Senior executive commitment (leadership and management), human resources, critical thinking, understanding root causes, solutions, and knowledge management are crucial for effective troubleshooting. An in-depth review of developing a troubleshooting culture is presented.

Keywords: troubleshooting, problem-solving, critical thinking, root cause, teams, culture

Introduction

For an organization to improve, it must have a culture that embraces change. The difficulty is determining and measuring organizational culture, which can be ambiguous and difficult to quantify. Organizational culture is a shared belief system consisting of an organization’s philosophy, traditions, shared expectations, work ethics, and values that hold it together.

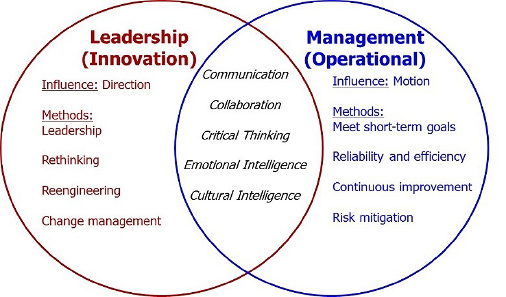

Both leadership and management are crucial for success. Leadership and management have specific individual responsibilities and shared organizational commonalities, see Figure 1. Leadership’s focus is on innovation. Leadership does this by influencing the direction of the organization. Methods include visionary leadership, rethinking, reengineering, and change management. Management’s focus is on operational excellence. Management does this by influencing the motion of human resources. Methods include meeting short-term goals, improving reliability and efficiency, mitigating risk, and continuous improvement. Senior executives must demonstrate commitment by actively supporting troubleshooting activities and being highly visible in the factory. Senior executives must articulate their commitment, using communication strategies to circumvent confusing intentions that can derail the troubleshooting culture. Senior executive commitment needs to be constant over time and relates more to how an organization approaches change than the actual change method specifics. Senior executives send encouraging signals and influence, inspire, and motivate the organization to adopt the troubleshooting culture. Ultimately, every employee’s job, from the janitor to the president, is to “solve problems and add value.”

Figure 1. Leadership and management.

Laying the Foundation for Troubleshooting

Establishing a troubleshooting culture requires three foundational pillars. Addressing these three pillars can significantly enhance its development and sustainability. Senior executives must customize these pillars based on site-specific needs and limitations. The three pillars and questions that senior executives must address are listed below.

Customer Quality Focus

How does the customer define quality? Does the organization have the capability to measure key quality attributes? How will evolving customer quality requirements be determined? How will customer poor quality issues be addressed?

Internal Organizational Quality Leadership

Do senior executives realize the need for and support a quality culture? How will organizational quality buy-in be achieved? How will the troubleshooting infrastructure be deployed? How will remedial training and new concepts be adopted and disseminated throughout the organization?

Continuous Improvement Troubleshooting

Which continuous improvement protocols (e.g., DMAIC, PDCA, etc.) will the organization use? Which continuous improvement tools will the organization use? How will inter-department, cross-department, and industry best practices be determined and implemented? Is the entire value stream viewed using a holistic systems approach? How will innovation be incorporated into continuous improvement activities?

Human Resources

Humans are hardwired to solve problems. Teams and teamwork are crucial for troubleshooting problems. Team members, and therefore, each team, have three problem-solving resources from which they can draw from. These problem-solving resources are technical knowledge (what do I know?), intellectual capacity (what ‘horsepower’ do I bring?), and cognitive style (how do I prefer to solve problems?).

Team members gain knowledge by working with experienced colleagues on various troubleshooting problems and projects. Intellectual capacity is an individual’s ability to think critically, see connections between disciplines, and problem-solve in changing situations. Cognitive style can be measured, enabling diversification of continuous improvement teams [1].

The Kirton Adaption-Innovation Inventory (KAI) measures cognitive style. When one applies their skills and intellectual horsepower to a problem, do they prefer creative adaption (Edison) or creative innovation (Einstein)? Dr. M.J. Kirton developed the Adaption-Innovation theory in 1976. KAI score distribution ranges from 40 (Adaption) to 150 (Innovation), see Figure 2. An individual’s KAI score is unaffected by age, IQ, job level, culture, or education level. There is a paradox of structure: We need it to solve problems… but too much limits us. Cognitive team diversity maximizes troubleshooting efforts and solutions. Diversified teams can resolve a wide range of strategic and tactical issues if they are developed. Cognitive diversity must be coached and challenged if it is to be exploited. Effective team troubleshooting embraces the paradox of structure by blending structured thinking with the unstructured creativity process.

Figure 2. KAI distribution of scores.

Critical Thinking

Critical thinking is the act or practice of thinking critically (by applying reason and questioning assumptions) to solve problems, evaluate information, and discern biases [2]. Troubleshooting encompasses three distinct types of thinking, all of which fall under critical thinking. These three areas of thinking are Systems, Scientific, and Statistical, which are crucial for troubleshooting problems. They are described below.

Systems thinking breaks down the value stream into three parts. The System is a collection of interrelated processes. Systemic is a holistic look at the collection of all processes. Systematic is an organized, step-by-step, scientific, and logical approach.

Scientific thinking is a five-step process. These five steps require the troubleshooting team to make observations, propose a hypothesis, design and conduct an experiment, analyze the data, accept or reject the hypothesis, and, if necessary, propose and test a new hypothesis. Scientific thinking promotes logical, not emotional, thinking.

Statistical thinking views all work as a function process, f(x1…xn) + error. It acknowledges that variation (error) exists in all processes and recognizes that knowledge and management of variation are critical for success.

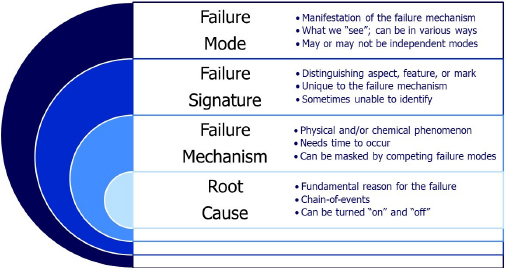

Understanding the Root Cause

A root cause is a factor(s) that caused a nonconformance and should be permanently eliminated through troubleshooting. The root cause is the core issue—the highest-level cause—that sets in motion the entire cause-and-effect reaction that ultimately leads to the problem(s) [3]. There are four stages on the path to understanding the root cause of a problem. These four stages are the Failure Mode, Failure Signature, Failure Mechanism, and the Root Cause. These are described below and summarized in Figure 3.

Figure 3. Four stages of understanding root causes.

The failure mode is the manifestation of the failure mechanism. Essentially, it is what we “see” and can be seen in various ways. It may or may not have independent modes. The failure signature is the distinguishing aspect, feature, or mark. It is unique to the failure mechanism. Sometimes, you are unable to identify the exact signature. The failure mechanism is the physical or chemical phenomenon driving the failure and needs time to occur. Competing failure modes can mask it. The root cause is the fundamental reason for the failure. It is the chain of events required for the failure to occur. It can be turned “on” and “off”.

Solutions

The Lean Six Sigma approach preaches that solutions should be simple, quick, and inexpensive. Simple solutions are user-friendly and reliable. Quick solutions are easily implemented and rapidly understood. Cheap solutions are affordable and economical. The troubleshooting team needs to be mindful of the 1:10:100 rule. One dollar spent on planning saves $10 on project work and $100 on fixing mistakes after project completion.

Knowledge Management

Knowledge management is about capturing, communicating, and preserving information. What do we capture? What is critical? What needs to be communicated? How do we communicate it? What actions should be taken? When should they be taken? How should the information be stored?[4, 5]

Conclusions

An organization needs leadership and management to nurture and develop a culture for troubleshooting. Humans are hardwired to solve problems. Team members have three problem-solving resources from which they can draw: technical knowledge (what do I know?), intellectual capacity (what ‘horsepower’ do I bring?), and cognitive style (how do I prefer to solve problems). Structured troubleshooting is required to solve problems… but too much structure limits us. Effective troubleshooting embraces the paradox of structure by blending structured thinking with the unstructured creativity process. Knowledge management is critical for documenting and retaining lessons learned.

References

[1] Kirton, M. (1976). Adaptors and innovators: A description and measure. Journal of Applied Psychology, 61(5), 622-629.

[2] Merriam-Webster Online Dictionary (2025). Retrieved from https://www.merriam-webster.com/dictionary.

[3] American Society for Quality (2025). Retrieved from https://asq.org/quality-resources/quality-glossary.

[4] Sobek II, D. K., & Jimmerson, C. (2004). A3 Reports: A tool for process improvement and organizational transformation. In Proceedings of the Industrial Engineering Research Conference, Houston, Texas.

[5] Biban, L. K., & Dhounchak, D. S. (2017). 8D Methodology: From Concept to Application Across Manufacturing Industries. International Journal of Scientific Research in Science, Engineering and Technology, Vol 3, Issue 6.

Biography

Patrick Valentine is the Technical and Lean Six Sigma Manager for Uyemura USA. He teaches Six Sigma Green Belt and black belt courses as part of his responsibilities. He holds a Doctorate in Quality Systems Management from Cambridge College, a Six Sigma Master Black Belt certification from Arizona State University, and ASQ certifications as a Six Sigma Black Belt and Reliability Engineer. Patrick can be contacted at pvalentine@uyemura.com