The Industry Standard for Gold Deposition, a Critical Tool for Corrosion Prevention

The purpose of IPC’s 4552 Rev A, ENIG Specification Revision is to reduce the lower limit of gold thickness and to establish an upper limit. Presently, those levels are 1.6 at -3 sigma, and 4.0 μins +3 sigma.

IPC 4552 Rev A also introduced a “Corrosion Inspection Methodology.” It said that for instances where heavier gold is a design requirement, alternate gold deposition methods should be used. The options for this included Electroless/ Autocatalytic Gold and Reduction-Assisted Immersion Gold.

The purpose for the corrosion evaluation is to ensure that good product that may exhibit minor corrosion is not rejected, and that product with excessive corrosion is rejected outright without the need for further failure analysis.

Corrosion evaluation is a way to characterize the ENIG process and its capabilities throughout the life of the nickel bath. Using the corrosion chart, the manufacturer has a way to detect corrosion early, determine an assignable cause and implement corrective action.

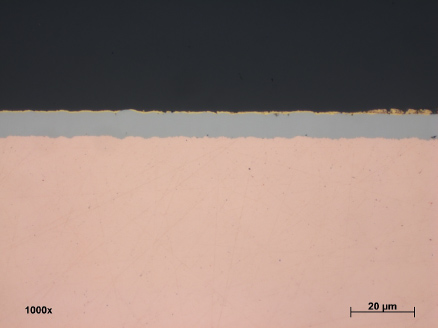

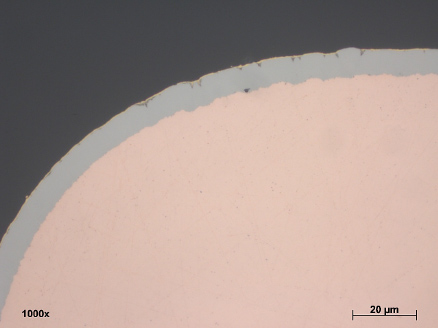

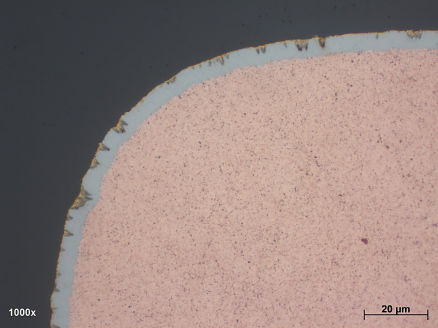

Identification of Hyper Corrosion Type on Individual Pad Using Optical Microscopy at 1000X

Classification into 3 levels is based on number and depth of defects (spikes, spreader spikes and black band)

| Level 1 | Level 3 | Level 2 |

|---|---|---|

|

or |

All other observations (> Level 1 and < Level 3) |

Click on images for detailed view

Description of Product Rating Levels

Product Rating Determines Accept/Reject Disposition

Level 1 hyper-corrosion - no effect on the functional performance of an ENIG deposit.

Level 2 hyper-corrosion - requires confirmation of proper formation of IMC on a soldered sample in order to assure the functional performance of an ENIG deposit.

Level 3 hyper-corrosion - considered to pose an unacceptably high risk of degraded functionality of an electroless nickel/ immersion gold deposit.

Product Rating Based on Hyper-Corrosion Investigation

| Product Rating | Hyper-Corrosion Investigation | Disposition |

|---|---|---|

| 0 | Defect-Free ENIG Deposit - Zero Evidence of Hyper-Corrosion | Target Condition |

| 1 | ≥60% of Investigated Locations Show Level 0 or 1 | Acceptable - This level of hyper-corrosion activity will not degrade solder joint integrity. |

| 2 | All Other Observations | Acceptable - May require extra analyses and testing to ensure acceptability. |

| 3 | >40% of Investigated Locations Show Level 3 | Rejectable - This level of hyper-corrosion will degrade solder joint integrity. |

IPC 4552 Rev A also specifies additional tests to determine acceptance or rejection of boards exhibiting Level 2 hyper-corrosion. For details on these tests and protocols for evaluation of ENIG deposits, click here.

IPC 4552 Rev B: Specification for ENIG Deposit Thicknesses

for Soldering, Wire Bonding and Contact Finishes

This newest IPC specification is pending. Its purpose will be to specify an inspection method, a rating method, and ultimately, to eliminate Ni corrosion in ENIG by improving the supplier’s process and the manufacturer’s process control. For details on this specification, and to be alerted when it is finalized, click here.