Tynades GHS-51 is the successor to GRX-70. It is an ultra-pure electrolytic tin plating process developed to prevent the formation of whiskers from all origins: oxidative corrosion, thermal expansion between the plating deposit and the material, intermetallic dynamics, coefficient of thermal expansion mismatches between the plating material and substrate, and external mechanical stress.

Tin whiskers pose a serious risk to electronic assemblies. Whisker crystals cause short circuits that bridge closely-spaced circuit elements maintained at different electrical potentials. Whiskers or parts of whiskers can break loose and bridge isolated conductors or interfere with optical surfaces.

Whiskers grow in both vacuum and earth-based atmospheric pressure. Whiskers of a few millimeters are common, with some up to 400 mils in length. Growth rates from 0.03 to 9 mm/yr. have been reported. Growth rate is variable and is influenced by plating chemistry and thickness, substrate, grain structure and storage conditions.

According to NASA, tin whiskers has induced short circuits resulting in complete failure of on-orbit commercial satellites on multiple occasions. There have also been whisker-induced failures in medical devices, weapon systems, power plants and consumer products. Notably, electrostatic attraction allows whiskers to bend, increasing the likelihood of tin whisker shorts.

GHS-51 works primarily by releasing compressive stress. It has very low carbon and sulfur content and is low-foaming in solution. A wide current density makes GHS-51 ideally suited for connectors and semiconductor lead frames. Selective plating is easy to accomplish, and the deposit has excellent solderability. Appearance following reflow is uniform white matte. While brighteners increase the risk of tin whiskers with traditional tin plating processes, this is not the case with GHS-51, which deposits as a pure tin, without the co-deposition of brighteners.

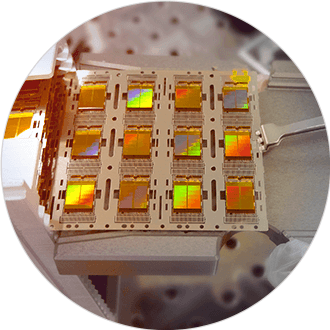

NTB-302 electrolytic tin produces a uniform coating of pure tin for chip resistors, chip capacitors, chip inductors, and other applications that can’t be exposed to acidic solutions. Deposited film of electrolytic tin has exceptionally uniform grain structure, plus:

- Neutral pH – minimal attack on pH sensitive devices

- Excellent solderability

- Excellent throwing power

- Low foaming bath; use with barrel or high-speed rotation electroplating equipment. Ideal plating with RP-1 equipment