Copper Chemistry Delivers Powerful Advantages in Process, Performance and Cost

Plating process has significant benefits for OEMs with multiple finishing operations, and contract shops who want to expand without capital expense.

KHW-NC (the “NC” indicates “no cyanide”) is a neutral pH, semi-bright alkaline copper that plates directly onto aluminum, and aluminum alloys with less than 1% silicon. It eliminates the necessity of double zincating prior to plating.

It is also a replacement for the cyanide copper strike used prior to zinc die cast plating. Bond strength on all these substrates is sufficient to pass the standard Heat-Quench Test, ASTM B571. Its small grain size means deposits are dense, highly corrosion-resistant, and resistant to thermal shock.

KHW-NC is exceptionally versatile: Deposit thickness will build with simple process adjustments. Making up the copper and conductivity salts at the low end of the range boosts throwing power and deposit uniformity. Making up the copper at the high end of the range can reduce process time. Lowering the bath pH produces a bright deposit; a higher pH produces a darker deposit.

KHW is stable, easy to run and virtually maintenance-free; only routine titration is needed. It operates at a temperate 150°F and is compatible with both rack and barrel equipment.

KHW provides important advantages in waste treatment, because it can be combined with other products in the waste stream, rather than treated separately – a huge benefit for finishers with multiple lines. The product is ammonia-free and does not contain EDTA or other chelating agents.

KHW-NC is a high-performing final finish, and an ideal under-plate for bright nickel / microcrack / chrome finishing. When used with a nickel barrier, it is also an excellent base for gold.

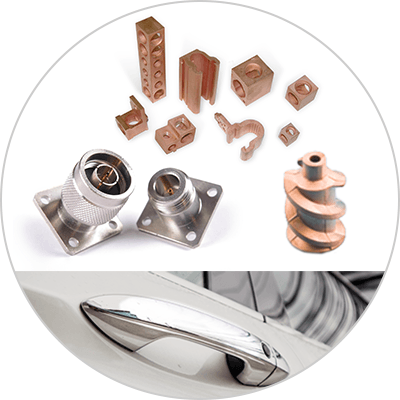

Specific applications for KHW include bumpers, door handles, grills, and connectors. Its excellent results on Heat-Quench Tests make it well suited for aircraft and other military applications, including engine and exterior components.