The ultimate in automated sampling, analysis and replenishment

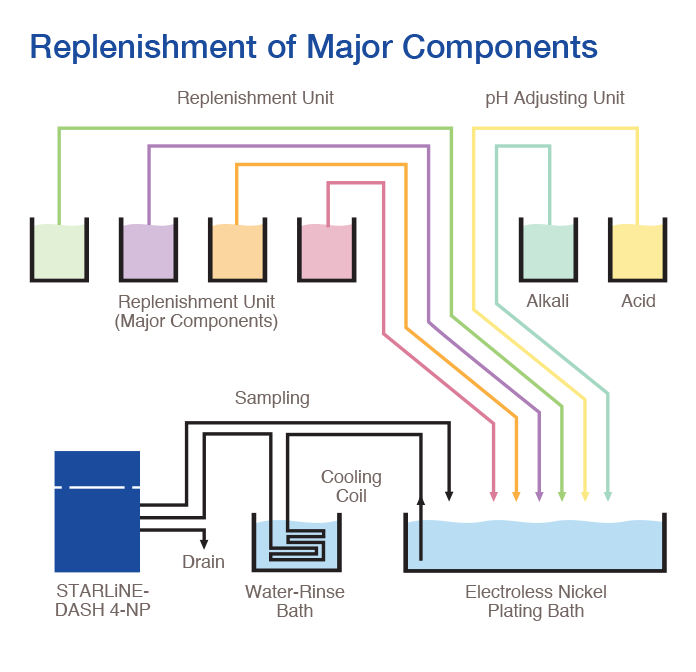

DASH 4-NP samples the electroless nickel plating solution, analyzes nickel and pH values, and replenishes automatically. As a result, baths can be maintained continuously at 2-4% of optimum, nickel can be controlled within +/-0.05 g/L, and overall plating rate can usually be increased.

It also offers these 12 important advantages:

- A foundation in the field-proven analysis protocols of the DASH NP-3

- Automatic pH and nickel calibration

- Pre-programming with parameters applicable to specific EN chemistry; simply select the plating product from the menu

- Data collection tabulates in situ without downloading with simple PC connection

- Controls up to two independent plating baths

- Intuitive operation via password-protected HMI

- Immediately displays real time analysis; will also display remotely

- Archives analysis and error records to removable USB memory

- Connects to an external monitoring system for real time bath condition monitoring

- Exceptionally "green;" plating rinse water cools sampling solutions, for example, precluding the need for additional cooling water. And because it reduces the amount of chemistry used, and the parts rejected, 4-NP contributes to pollution prevention.

- Side-accessible reservoir column

- Precise tracking of chemical use, bath age, and replenisher inventory

Starline-Dash™ 4-NP operators review system history, establish sampling schedules, calibrate bath sensors, and specify tolerances; the system does the rest.

-

As a result:

- Deposition rates are kept exceptionally uniform.

- The plating line can perform at maximum productivity, even when loading is highest.

- Management has a proven way to control costs and rejects.

-

Starline-Dash™ 4-NP Provides Ultimate Control for Uyemura EN Chemistries:

- NIMUDEN™ NPR-4 Electroless Nickel

- EPITHAS™ NPR-18

- NIMUDEN™ ANP Electroless Nickel

- NIMUDEN™ NPR-8 EN-phosphorus

- KTY Electroless Nickel

Download the STARLiNE DASH™4-NP Brochure

RP-2 Flow-Thru Electrolytic Plating System for SMT Micro Components

Plates as Small as 50µm Without Agglomeration

This fully automatic plater uses high speed rotation and centrifugal force to optimize electrical contact between the plating material and cathode. It also uses inertia when the equipment brakes to a rapid stop to force fluid mixing of the plating material. This ensures a homogeneous deposit thickness, as well as high current density operation that is substantially greater than what’s technically possible with conventional barrel plating. The RP-2 is ideal for electrolytic plating of nickel, tin and copper plating, as well as fine powders.

-

Process Features:

- Plates 3-5X faster than traditional barrel systems

- Exceptional deposit uniformity

- Filter changes make enable plating with fine powders (10-50 µm)

- Accommodates chip capacities of 2 mil X 1 mil

-

Environmental Features:

- Enclosed process manages fumes and evaporation

- Minimal drag-out design

- Does not require media for plating

-

System Features:

- Dual-chemical reservoirs standard

- User programmable logic control, with touch screen interface

- Equipped for R&D or production

- Environmentally friendly, labor-saving design

- Process plating (first plate, rinse, second plate) can be performed in one module.

- The number of modules can be increased to suit user specifications.