By April Labonte and Brittany Malin

Uyemura International Corporation

Southington CT

Abstract

Establishing robust guidelines for Measurement System Analysis (MSA) is paramount in the PCB industry. It is a critical factor in ensuring the quality and reliability of key surface finish processes, such as Electroless Nickel Immersion Gold (ENIG). This paper illustrates the effects of measurement variability on bias and linearity over a specified range of thicknesses. By implementing these guidelines, PCB manufacturers can significantly enhance the reliability of their MSA processes, reduce measurement uncertainties, and improve overall quality control.

Keywords: Measurement System Analysis (MSA), PCB Industry, ENIG, Bias, Linearity, Quality Control, Surface Finish.

Introduction

Measurement system analysis (MSA) is used to evaluate the overall capability of a measurement system. Measurement capability is a foundational element of ensuring product quality, as reliable measurements are essential for maintaining consistency and meeting specifications. Before any measurement system is used in production, it must undergo a thorough evaluation to determine its capability. This assessment ensures the system can provide accurate and precise measurements, laying the groundwork for robust quality control practices.

A capable measurement system should be both precise and accurate. Precision refers to the variability of the gauge by looking at how close the measurements are to each other when repeat measurements are taken. When determining the precision of a measurement system, it should be deemed repeatable and reproducible. Accuracy refers to the closeness of a measured value to a standard or reference value. There are many tools that can be utilized to evaluate the MSA of a process.

The Type 1 Gauge study is a common starting point in a comprehensive MSA program. This study involves repeated measurements of a single sample using one gauge and one operator, providing insights into both the accuracy of the gauge by comparing results to a reference value and its precision through the consistency of repeated measurements. In industry, it is common to pick a reference value standard in the center of the measurement range. Traditionally, a NIST traceable standard is utilized. Typically, 30 measurements are taken, and the capability indices (Cg and Cgk) are evaluated. If the gauge achieves a minimum capability index of 1.00, it is deemed acceptable. However, a comprehensive MSA program goes beyond this initial evaluation, providing a more thorough and reliable assessment of the measurement system's capability.

A comprehensive MSA program is essential for complex processes in the Printed Circuit Board (PCB) manufacturing industry, particularly for surface finishes such as Electroless Nickel Immersion Gold (ENIG). While a Type 1 Gauge study is a useful starting point for evaluating a measurement system, it has limitations. The study evaluates the gauge's performance at a single point and does not account for variability across a range of values. For processes requiring measurements over a range of thicknesses or parameters, this limited focus can overlook variability in accuracy (bias) and precision (repeatability) that may occur at different points within the range. To ensure a robust measurement system, additional statistical studies are needed to assess performance across the entire operating range.

In manufacturing, these measurement system challenges are compounded by the risks of Type 1 and Type 2 errors, which influence scrap and quality outcomes. A Type 1 error (false positive) occurs when a good part is mistakenly rejected as defective, leading to unnecessary scrap or rework. On the other hand, a Type 2 error (false negative) happens when a defective part is wrongly accepted as good, potentially leading to quality issues downstream or with customers. Minimizing these errors is critical to reducing waste and ensuring product reliability. The gauge's bias and linearity need to be evaluated to avoid these risks.

Performing a Bias & Linearity Study (B&L) is crucial in avoiding these Type 1 and Type 2 errors. Bias refers to the difference between the average measurement and the known standard being measured. Linearity refers to the difference in bias throughout the gauge's application range. The B&L study plays a significant role in identifying and addressing these issues, thereby enhancing the reliability of the MSA process, reducing measurement uncertainties, and improving overall quality control [1,5].

Methods and Materials

To run a bias and linearity gauge study, select a minimum of five representative parts across the measurement range of the gauge. Each reference part must have a known measurement value and collectively represent the full range of actual or expected measurements. The reference values should be NIST traceable. One operator should perform all the measurements, at least five per reference part, and the data should be collected randomly. Measurement times should be determined by the smallest measurement time required to reach acceptable Cg and Cgk values on a Type I Gauge study. Once the measurements are taken, statistical analysis can be performed [4].

To analyze the bias and linearity of the gauge, start by looking at the fitted regression line on the bias versus reference value plot. A regression line is fitted to the bias values using ordinary least squares regression [6]. Ideally, the plot should have a horizontal line through the values indicating the bias does not change across the reference parts and the bias of the measurement system is negligible. If the plotted line is sloped, linearity is an issue, and the gauge linearity needs to be evaluated. Generally, the closer the slope of the fitted line is to zero, the better the gauge linearity.

Once this visual check is complete, the next step is to evaluate the gauge linearity using the p-value for the slope of the fitted line. If the p-value is greater than 0.05, linearity is not present, and continue assessing the system's bias. However, if the p-value is less than or equal to 0.05, this indicates an issue with linearity. In this case, it is impossible to assess the gauge's overall bias. Instead, interpret the p-values for the individual reference values only [4].

After evaluating linearity, the final step is to assess the bias of the measurement system. In an ideal scenario, the bias should remain consistent throughout the application range. A positive bias indicates the gauge is measuring high, and a negative bias indicates the gauge is measuring low. If linearity is not present, the p-values can be used to interpret the overall bias. For each reference value, if the p-value is greater than 0.05, conclude that the bias equals zero. For the average bias, if the p-value is greater than 0.05, conclude that the average bias is equal to zero. If the p-value is less than or equal to 0.05, conclude that the bias is not equal to zero [4]. This may indicate a problem with the reference standard, a systematic problem in the equipment, or a faulty measurement procedure. A solid understanding of the process is important to determine whether the statistically significant bias is also a practical difference.

Example

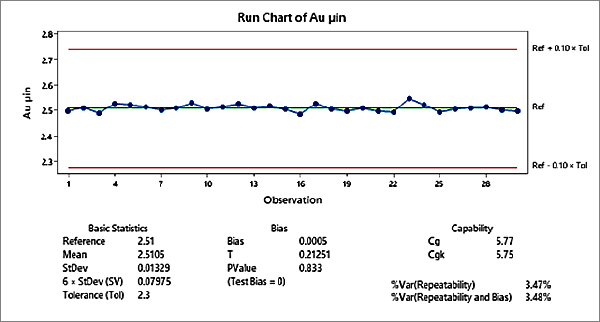

Using an ENIG calibration program, an example was performed to assess the measurement capability of a Bowman K-series x-ray fluorescence (XRF) unit. The XRF was calibrated using three ENIG standards with gold thicknesses of 1.02μin, 2.51μin, and 4.09μin to encompass the entire gold range as defined in the IPC-4552B specification [3]. After calibration, a Type 1 Gauge Study was completed using the 2.51μin standard by taking 30 measurements at 30 seconds, as shown in Figure 1. The Type 1 Gauge Study yielded acceptable capability indices with a Cg value of 5.77 and a Cgk value of 5.75. Following the IPC-4552B specification, the XRF unit would be considered capable [3].

Figure 1. Type 1 Gauge Study

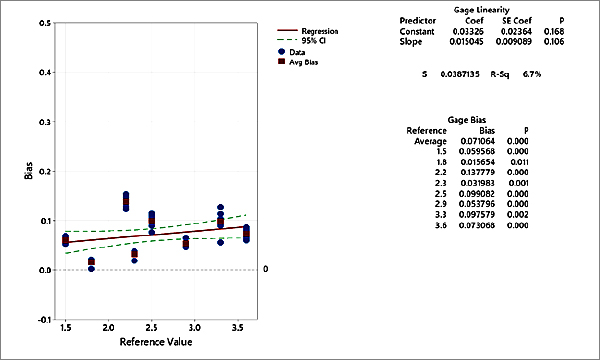

To further assess the capability of the gauge, a Bias and Linearity Study was completed, as shown in Figure 2. Initially, the B&L study was done with eight reference samples with gold thicknesses between 1.5 and 3.6μin. These thicknesses were selected to best represent the gold thickness range as stated in the IPC-4552B specification [3]. The p-value for the slope was 0.106, greater than 0.05, indicating issues with linearity were not present. The p-value for the bias was 0.000, less than 0.05, indicating the bias is not equal to zero. While statistically significant, the bias value of 0.07 is not practically significant. This gauge would be considered capable of the standard IPC-4552B gold thickness range [3].

Figure 2. B&L Study Eight Reference Parts

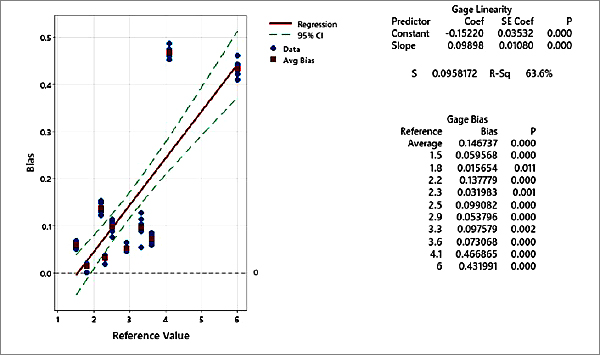

To evaluate the performance of the XRF system beyond the standard industry gold thickness range, additional reference samples were selected at 4.1μin and 6.0μin, as shown in Figure 3. While IPC-4552B typically defines acceptable ENIG thicknesses for nickel and gold, in production, parts exceeding this range can occur due to customer requirements or process drift. The gauge's bias and linearity in each case were assessed by testing parts outside this window, where process monitoring and measurement accuracy are especially critical.

Figure 3. B&L Study Ten Reference Parts

This study revealed a linearity issue at the range's extremes, with the bias's slope versus reference value plot deviating significantly from zero (p-value less than 0.05). Once operating outside the IPC-4552B range, there is a statistical and practical bias of approximately 0.5μin. This suggests that the measurement system's accuracy is not consistent across the full operating range. These deviations can lead to misclassification of parts. For example, if bias causes a conforming product to appear nonconforming, this can result in unnecessary rework or scrap. Conversely, if the gauge underestimates thickness in critical areas, a defective part may be accepted and released to the customer. These measurement errors undermine product quality, increase operating costs, and damage customer relationships.

When only a limited number of standards are used, particularly those concentrated around the nominal value or the center of the range, the behavior of the measurement system at the upper and lower ends can go uncharacterized as seen in this example. This incomplete picture can mask significant issues such as inconsistent bias across the range or a lack of linearity in certain regions. By selecting standards that encompass the entire measurement range, the gauge capability becomes more representative of the whole process. This approach supports more accurate statistical analysis, narrower confidence intervals, and improved detection of systematic error. The Measurement Systems Analysis Reference Manual, published by the Automotive Industry Action Group, recommends evaluating measurement systems across their full operational range to ensure reliable data and trustworthy decision-making [2].

Conclusion:

Incorporating a bias and linearity study into the current MSA process will significantly enhance gauge capability and support the pursuit of world-class quality. Neglecting to perform a full measurement system analysis that includes bias and linearity studies can result in the use of unverified data throughout the production process. This false sense of measurement reliability introduces process risk and prevents accurate root cause analysis. Engineers may respond to what they believe are real trends or issues when acting on flawed data [6]. In the worst-case scenario, defective products may reach the customer, leading to field failures, warranty claims, or brand erosion. These consequences are especially critical in industries that rely on high-reliability electronics.

References

[1] Abdelgadir, M., Gerling, C., Dobson, J. (2020). Variable Data Measurement Systems Analysis: Advances in Gage Bias and Linearity Referencing and Acceptability.

[2] AIAG. (2010). Measurement Systems Analysis (MSA) Reference Manual (4th ed.). Automotive Industry Action Group.

[3] IPC International. (2020). IPC-4552B: Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Circuit Boards.

[4] Montgomery, D. C. (2017). Introduction to Statistical Quality Control (7th ed.). Wiley.

[5] Simion, C. (2015). Assessing Bias and Linearity of a Measurement System.

[6] Wheeler, D. J. (2006). EMP III: Evaluating the Measurement Process & Using Imperfect Data.

Biography

Brittany Malin is the Laboratory & Continuous Improvement Manager for Uyemura USA. She holds a Bachelor’s of Science Degree in Chemistry and Mathematics from Central Connecticut State University and ASQ certifications as a Six Sigma Black Belt and Reliability Engineer. Brittany can be contacted at bmalin@uyemura.com.

April Labonte is the North American Technical Manager for Uyemura USA. She holds a Bachelor’s of Science Degree in Chemical Engineering from the University of California San Diego. April can be contacted at alabonte@uyemura.com.

Acknowledgement

The authors would like to acknowledge Bowman XRF for their generous support in providing access to their instrumentation and assisting with data collection. The use of the Bowman K-series XRF was instrumental in conducting our measurement system analysis.