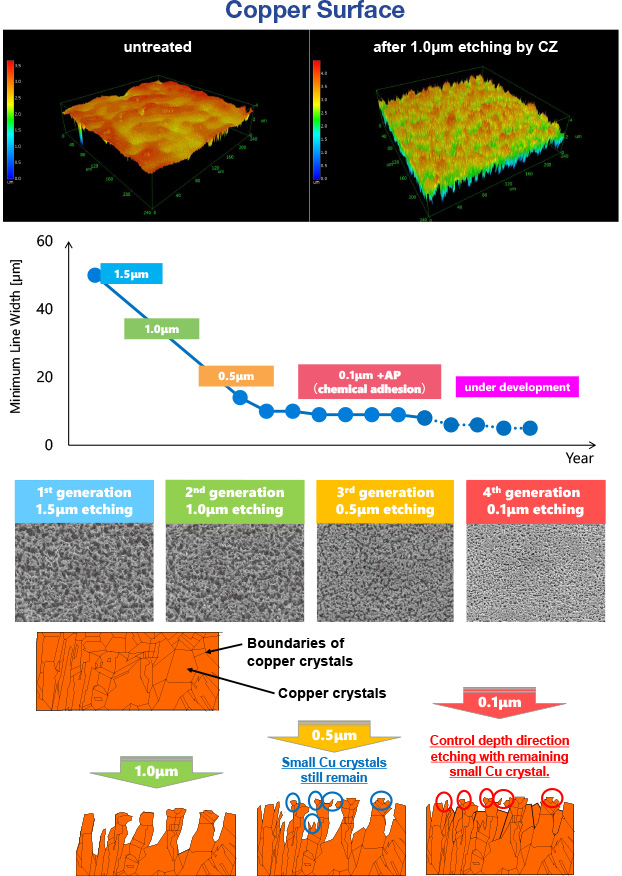

CZ Roughening Treatment

Creating the best copper surface topography for the best product reliability.

MECetchBOND CZ Series Our organic-acid type copper micro-etching solution creates a unique roughened surface and achieves a higher physical adhesion to a variety of resins, including build-up resin, dry film etch resist and solder mask.

SILKYSURF AP Series This process improves the adhesion of copper and resin by combining an ultra-low etched, unique roughened surface and an organic film. It achieves the best adhesion to a variety of resins with a minimal loss of pattern dimensions.

Bonding by Anchor Effect MEC’s CZ series produces a unique super-fine surface roughness by preferential etching of copper surfaces. When resin systems are applied to this super-fine roughened surface, they will flow into this roughness and after solidifying, create a very strong bond due to the ‘anchor effect’.

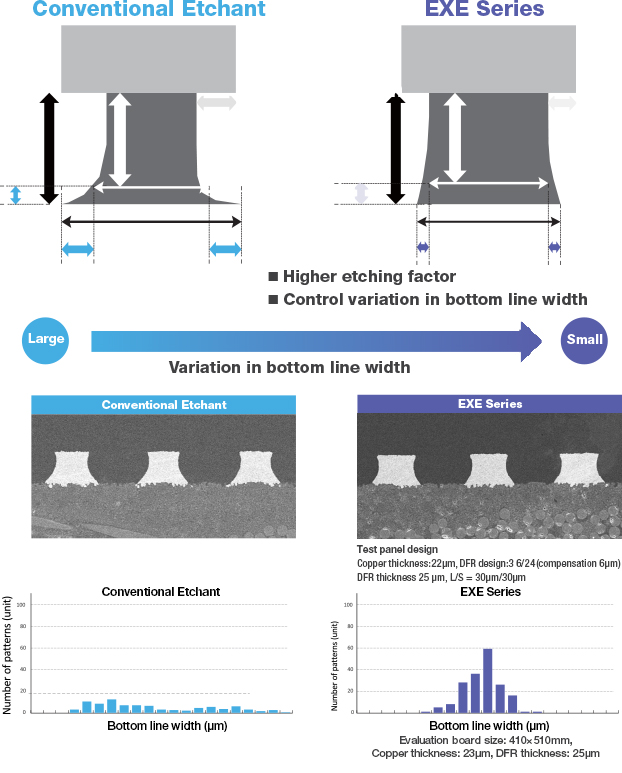

Anisotropic etching improves etch factor and realizes finer patterns with copper chloride etching.

MECBRITE EXE Series Compatible with standard acid etching processes.

Features of EXE Series

- An additive agent for copper chloride etchant.

- Higher EF than a standard copper chloride etchant.

- Less pattern width variation after etching.

- No need to change your existing etching line.

- General controller can be used.

- Both hydrogen peroxide and sodium chlorate

can be used as oxidizers.

Etchant for Ti Seed Layers

MEC REMOVER QT-1100 is a highly selective etchant that removes 50 nm titanium seed layer from a board where copper and titanium coexist. Action is within 60 seconds by flood-immersion. QT-1100 has minimal impact on copper, and excellent liquid stability; it is free of hydrofluoric acid, ammonia, and hydrogen peroxide.

Etchant for Inkjet Soldermask Processes

MECetchBOND CL-8325C is an anti-bleed pre-treatment for Inkjet Solder Mask Processes. Used with MEC CZ treatment, CL-8325C improves adhesion to the Inkjet soldermask by roughening the copper surface, while preventing the soldermask from bleeding onto the copper and resin. Standard operating temperature is 25°C; standard contact time is 30 seconds.

The pairing of CZ and CL-8325 streamlines the process from the 5 steps required by conventional methods, to just 3, resulting in an overall reduction in process cost.

Etchant Additive

MGE-9 is an additive for H2O2 / H2SO4-type etchants that reduces copper roughness and promotes adhesion, thereby producing an ideal copper surface for surface finish plating. The MGE-9 process produces a smoother copper surface than sodium persulfate or standard hydrogen peroxide/sulfuric etchants. The etch rate is consistent throughout the life of the bath and is unaffected by increases in copper concentration.